Variable Gage R&R with JMP

What is Variable Gage R&R?

Variable Gage Repeatability & Reproducibility (Gage R&R) is a method used to analyze the variability of a measurement system by partitioning the variation of the measurements using ANOVA (Analysis of Variance). Whenever something is measured repeatedly or by different people or processes, the results of the measurements will vary. Variation comes from two primary sources:

- Differences between the parts being measured

- The measurement system

We can use a Gage R&R to conduct a measurement system analysis to determine what portion of the variability comes from the parts and what portion comes from the measurement system. There are key study results that help us determine the components of variation within our measurement system.

Variable Gage R&R primarily addresses the precision aspect of a measurement system. It is a tool used to understand if a measurement system can repeat and reproduce and if not, help us determine what aspect of the measurement system is broken so that we can fix it.

Gage R&R requires a deliberate study with parts, appraisers and measurements. Measurement data must be collected and analyzed to determine if the measurement system is acceptable. Typically Variable Gage R&Rs are conducted by 3 appraisers measuring 10 samples 3 times each. Then, the results can be compared to determine where the variability is concentrated. The optimal result is for the measurement variability to be due to the parts.

What is Measurement System Analysis?

Measurement System Analysis (MSA) is a systematic method to identify and analyze the variation components of a measurement system. It is a mandatory step in any Six Sigma project to ensure the data are reliable before making any data-based decisions. A MSA is the check point of data quality before we start any further analysis and draw any conclusions from the data. Some good examples of data-based analysis where MSA should be a prerequisite:

- Correlation analysis

- Regression analysis

- Hypothesis testing

- Analysis of variance

- Design of experiments

- Statistical process control

You will see where and how the analysis techniques listed above are used. It is critical to know that any variation, anomalies, or trends found in your analysis are actually due to the data and not due to the inaccuracies or inadequacies of a measurement system. Therefore the need for a MSA is vital.

Measurement System

A measurement system is a process used to obtain data and quantify a part, product or process. Data obtained with a measurement device or measurement system are the observed values. Observed values are comprised of two elements

- True Value = Actual value of the measured part

- Measurement Error = Error introduced by the measurement system.

The true value is what we are ultimately trying to determine through the measurement system. It reflects the true measurement of the part or performance of the process.

Measurement error is the variation introduced by the measurement system. It is the bias or inaccuracy of the measurement device or measurement process.

The observed value is what the measurement system is telling us. It is the measured value obtained by the measurement system. Observed values are represented in various types of measures which can categorized into two primary types discrete and continuous. Continuous measurements are represented by measures of weight, height, money and other types of measures such as ratio measures. Discrete measures on the other hand are categorical such as Red/Yellow/Green, Yes/No or Ratings of 1–10 for example.

Variable Gage R&R Guidelines (AIAG)

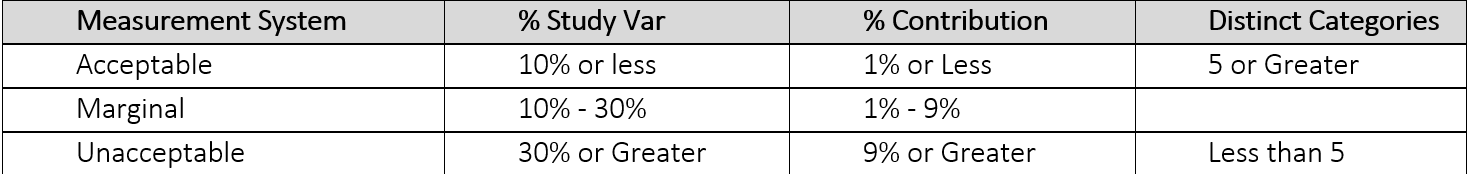

The guidelines for acceptable or unacceptable measurement systems can vary depending on an organizations tolerance or appetite for risk. The common guidelines used for interpretation are published by the Automotive Industry Action Group (AIAG). These guidelines are considered standard for interpreting the results of a measurement system analysis using Variable Gage R&R. The table below summarizes the AIAG standards.

Use JMP to Implement a Variable MSA

Data File: “VariableMSA.jmp”

Let’s take a look at an example of a Variable MSA using the data in the Variable MSA tab in your “Sample Data.xlsx” file. In this exercise we will first walk through how to set up your study using JMP and then we will perform a Variable MSA using 3 operators who all measured 10 parts three times each. The part numbers and operators and measurement trials are all generic so that you can apply the concept to your given industry. First we need to set up the study.

Run Variable MSA in JMP:

Step 1: Initiate the MSA study

- Click: Analyze > Quality & Process > Measurement Systems Analysis

- Select “Measurement” as “Y, Response”

- Select “Operator” as “X, Grouping”

- Select “Part” as “Sample, Part ID”

- Select “Gauge R&R” as the “MSA Method”

- Select “Crossed” as “Model Type”

- Click “OK”

Step 2: Create the variability chart for measurement

- Click on the red triangle button next to “Variability Gauge”

- Click “Connect Cell Means” to link the average measurement for each part together

- Click “Show Group Means” to display the average for each appraiser (solid line)

- Click “Show Grand Mean” to display the average for the entire data set (dotted line)

Step 3: Implement Gauge R&R

- Click on the red triangle button next to “Variability Gauge”

- Click “Gauge Studies” -> “Gauge RR”

- A window named “Enter/Verify Gauge R&R Specifications” opens

- Enter the specified value into “K, Sigma Multiplier” box. In this example, we use 5.15 to assume a 99% spread of the data

- Click “OK”

Step 4: Create Mean Plots for further analysis

- Click on the red triangle button next to “Variability Gauge”

- Click “Gauge Studies” -> “Gauge R&R Plots” -> “Mean Plots”

- Three plots appear

Model summary: The result of this Gage R&R study leaves room for consideration on one key measure. As noted in previous pages, the targeted percent contribution R&R should be less than 9% and study variation less than 30%. With % contribution at 7% it is below our 9% unacceptable threshold and similarly, Study variation at 26.1476% is also below the threshold of 30% but this result is at best marginal and should be heavily scrutinized by the business before concluding that the measurement system does not warrant further improvement.

Visual evaluation of this measurement system is another effective method of evaluation but can at times be misleading without the statistics to support it. Diagnosing the mean plots above should help in the consideration of measurement system acceptability, you may benefit from taking a closer look at operator C.

Hi Denise,

Reading through this I don’t understand where the results of the study are shown. It says the contribution from R&R is 11% and the study variation is 34.126% and that the distinct categories is 3, I don’t see this displayed in the data. Can you show me where I can find these numbers in the tables/charts?

Hi Scott,

Thank you for your inquiry. I have reviewed the post and your question and determined that we had updated images relative to previous JMP version updates (v.11 vs. v.13) and it appears your question has alerted us to the error of not fully updating the text relative to the new JMP v.13 statistical and graphical outputs. I have made these changes to the post and we will be including necessary edits to our books as well. Thank you for being a concerned reader of our content. I will be happy to respond further if you have follow up questions.

Great article!

Any suggestions if the tool has multiple chambers or sockets? For example if a tester can test four chips at once how would you modify this test to address the four sockets?

I keep getting the error “Continuous part column not supported for random effects.

Hi Mark,

I can’t be sure without seeing it, but if I had to guess I’d say you’re either pointing to continuous data or your column attributes need to be changed to discrete.