Six Sigma Approach

The Six Sigma approach to problem solving uses a transfer function. A transfer function is a mathematical expression of the relationship between the inputs and outputs of a system.

The Six Sigma approach to problem solving uses a transfer function. A transfer function is a mathematical expression of the relationship between the inputs and outputs of a system.

Y=f(x) is the relational transfer function that is used by all Six Sigma practitioners. It is absolutely necessary to understand and embrace this concept if you wish to be a serious practitioner of Six Sigma.

The ‘Y’ refers to the measure or output of a process and it’s usually your primary metric or the measure of process performance that you’re trying to improve.

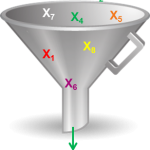

f(x) means “function of x”. X’s are the factors or inputs that affect the “Y”. Combined, the Y=f(x) statement reads: “Y is a function of X.” or, in simple laymen terms: “My process performance is dependent on certain X’s”.

The objective in a Six Sigma project is to identify the critical X’s that have the most influence on the output (Y) and adjust or control them so that the “Y” improves.

Let’s look at a simple example of the relationship of Y=f(x) using a pizza delivery company that desires to meet customer expectations of on time delivery..

- Primary Metric = on time pizza deliveries

- “Y” = percent of on time deliveries

- “f(x)” = X’s or factors that heavily influence on time delivery

- x1: might be traffic

- x2: might be the number of delivery’s per driver dispatch

- x3: could be the poor directions provided to the driver

- x4: may be the reliability of the delivery vehicle

The statement Y=f(x) in this example will refer to the proven X’s determined through the steps of a Six Sigma project. With this approach all potential X’s are evaluated through.