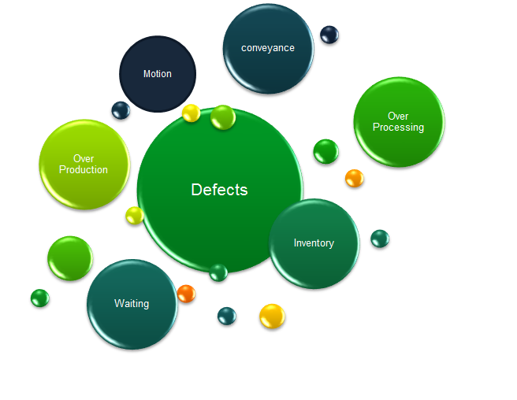

Seven Deadly Muda

Muda is a Japanese word meaning WASTE. As you should have already learned, waste is a not even remotely desirable and Lean principles seek to eliminate waste.

As such, the seven common forms of waste have taken on the moniker of the "Seven Deadly Muda" They are as follows:

- Defects

- Over Processing

- Inventory

- Motion

- Transportation

- Waiting

- Over Production

Defects

Defects or Defectives are an obvious waste for any working environment or production system. Defects require rework during production and/or after the product is returned from an unhappy customer.

Some defects are difficult to solve and they create “work-arounds” and hidden factories. Eliminating defects are a surefire way to improve product quality, customer satisfaction and production costs.

Over Processing

Over-processing is working more or harder than is necessary. Over-processing occurs any time more work is done than is required by the next process step, operation or consumer. This includes being over capacity or scheduling more workers than required or having more machines than necessary (overkill).

Another form of over processing can be buying tools or software that is wasteful (having more precision than needed, employing software systems that are more complex or expensive than required).

Inventory

Inventory is an often overlooked waste. Look at the image at left and imagine all the time, materials, and logistics that went into establishing such an abundance of inventory.

If this were your personal business and inventory velocity was not matched with production how upset might you be?

Motion

Motion is another form of waste often occurring as a result of poor set-up, configuration or operating procedures. Wasted motion can be experienced by machines or humans.

Wasted motion is very common with workers who are unaware of the impact of small unnecessary movements in repetitive tasks. Wasted motion is exaggerated by repetition or re-curing tasks.

Transportation

Transportation is considered wasteful because it does nothing to add value or transform the product. Imagine for a moment driving to and from work “twice” before getting out of your car to go into work….That’s waste in the form of transportation.

The less driving you have to do the better. In a similar way, the less transportation a product has to endure the better. Fewer opportunities for delay, destruction, loss, damage etc.

Waiting

Waiting is an obvious form of waste and is typically a symptom of an upstream problem. Waiting is usually caused by in-efficiency, bottlenecks or poorly designed work flows within the value stream.

Waiting can also be caused by inefficient administration. Reduction in waiting time will require thoughtful applications of lean and process improvement.

Over Production

Over production is the act of producing more product than is required. It causes your system to expend energy and resources on production of materials not required by the customer or a downstream function. Over Production is the most detrimental of the seven deadly muda because it has a direct correlation to all other wastes. It creates Inventory and inventory requires transportation. Over-Production also creates more opportunities for defects and assuming your process has inherent waste in the form of waiting and motion, over-production exacerbates those issues. Lastly, over-production itself is also over-processing.