How to Define a Process

The essential method for how to define a process is without question the process map. The process map helps you to understand a process and its component steps. Process maps help determine where and how a process begins and ends as well as all the steps and decisions in between. By learning the basics of process mapping you can become adept at:

The essential method for how to define a process is without question the process map. The process map helps you to understand a process and its component steps. Process maps help determine where and how a process begins and ends as well as all the steps and decisions in between. By learning the basics of process mapping you can become adept at:

- Understanding how to document an existing process

- Learn how to depict the "as is" or current state of a process

- Identify areas of inefficiency in a process

There are a number of process map types (high level, detailed, functional etc.). In the Measure phase of Six Sigma we even touch on more advanced types of process mapping such as value stream maps and SIPOC. In this article however, we are focused on how to define a process by learning the basics of process mapping and how to use a high level process map.

What is a Process Map?

A process map is a graphical representation of a process flow. A process map illustrates how a product is made or how a transaction is performed. Process maps represent these activities in a step by step manner. Process maps also help represent how materials or information sequentially flow from one business entity to the next. Some process maps even help demonstrate who is responsible for each step.

How do I make a process map?

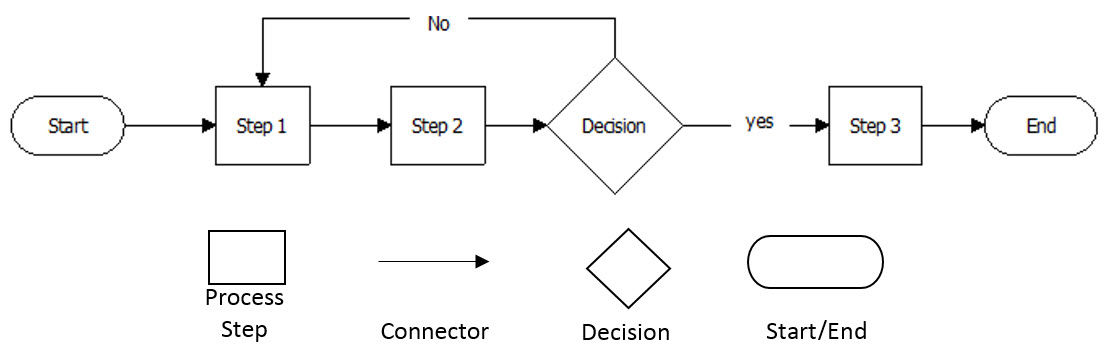

The most commonly used process mapping symbols are listed under the process map below. These are the essential four symbols. It is unlikely that any process map is ever made without using all four of these symbols. They represent the most basic and common graphical elements necessary to draw your first process map, and even your most advanced one. Process maps start and end with the oval symbol labeled above as "start/end". All maps then have process steps and most have decisions. In order to draw your first process map you must identify the process that you want to map and begin by labeling the first step with the oval. The very next step in a process should then be represented with a square. If successive process steps ensue, continue using a square. If you encounter a place in the process where a decision must be made then represent that question/decision with a diamond symbol. All decisions have more than one possible result. Therefore, most diamonds have 2 connectors pointing to separate process steps. Typically these pointers represent "Yes" and "No" answers to the question or decision. Below is a simple generic process map example:

As a general rule I suggest that high level process maps be limited to 4-6 steps. The key is being able to condense a process into logical groups of easily descriptive categories. If you cannot condense a process down to its simplest form and represent it in 4-6 steps then you probably don't understand the process well enough or your are a victim of over complicating things.

There will no doubt be a need to further refine the level of information and detail represented by your process map but the first step should always be to map it in its most basic form. We have process mapping techniques that will help you add detail in a structured and organized manner but that lesson is for another day. Today, accept the challenge of mapping your process in 4-6 steps...Can you do it?