Getting Your Primary Metric Right

Before any six sigma project can get off the ground successfully, there is one critical metric that must be identified, the primary metric. In the DMAIC process, the define stage allows ample opportunity to clearly identify what the project will impact. This leads to the assignment of establishing your primary metric. The primary metric is the measurement of the identified improvement in your project. In the foundation of Six Sigma, the equation y= f(x) creates the visualization of measuring what you can manage. The manageable parts of a project or process, otherwise known as the inputs, are the X’s in the equation. As they are changed or improved, they change the measurable outputs, or the Y in the equation. Correctly choosing the primary metric based on the understanding of the y=f(x) function clarifies the purpose of the project, as it becomes the most important measurement of success.

Before any six sigma project can get off the ground successfully, there is one critical metric that must be identified, the primary metric. In the DMAIC process, the define stage allows ample opportunity to clearly identify what the project will impact. This leads to the assignment of establishing your primary metric. The primary metric is the measurement of the identified improvement in your project. In the foundation of Six Sigma, the equation y= f(x) creates the visualization of measuring what you can manage. The manageable parts of a project or process, otherwise known as the inputs, are the X’s in the equation. As they are changed or improved, they change the measurable outputs, or the Y in the equation. Correctly choosing the primary metric based on the understanding of the y=f(x) function clarifies the purpose of the project, as it becomes the most important measurement of success.

How Do You Know Your Primary Metric Is Right?

The first element essential to making the right choice for your primary metric is that the measurement can be expressed in an equation. The equation does not need to be a detailed mathematical function – in fact, it should be easily explained to ensure that all team members are able to understand the goals of the project. A primary metric most successfully measures change as a proportion, sum or count, all of which are expressed easily among the project team. This equation creates a tangible measurement that can be aligned to business goals, keeping projects and teams focused on the bigger picture.

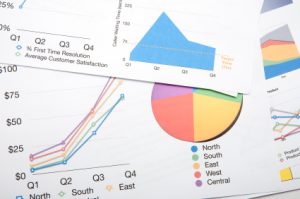

The second element critical in getting your primary metric right is the frequency at which data can be collected to understand how a specific change is impacting the measurement. A primary metric should have the ability to be tracked at a regular frequency, creating visibility for project teams and management. Additionally, the frequency of data collection affects the project timeline. Data collection that requires a long waiting time may increase a project timeline, and since decisions should not be made on a single data point, the chosen primary metric may be an unacceptable measure of the success of that project. For example, if you’re measuring at monthly intervals then it will reasonably take several months of “results” before you’re able to prove a real change. If this timeline is too long then you should consider measuring at weekly or daily intervals.

Knowing Where You Started

Getting your primary metric right requires a clear baseline to properly manage expectations of success. If there is no data to identify current state, there is no way to identify if there has been a positive or negative change due to an input. Creating a baseline with your primary metric gives your project a clear starting point. A well-defined primary metric is also time bound, specific, and realistic – all qualities that can be identified early in a project by establishing a baseline. Having a baseline gives you the starting point for the primary metric, a picture of the current state and shows you how far away from the goal you are. Thus, helping to quantify cost of poor quality. Then, it will serve as an indicator showing you through variation, what factors may be the key influencers to making favorable changes and getting to your goal.

The primary metric is the most important measure of success in any six sigma project, hence, why getting it right is so crucial. When identifying it, keep in mind the importance of always understanding the equation that it represents, have the ability to collect the proper amount of data at the right frequency, and ensure that there is a clear baseline to measure success. Once you have gotten your primary metric right, you can start determining the inputs that will create positive, or desired, changes in your output.